If you can’t measure it or see it, you can’t improve it. The more visual you make your factory floor the more productive and efficient you can make it run

5 min read

What is a Visual Factory?

Visual Factory is a concept that is widely used in lean-sigma methodologies to communicate information quickly and easily. The term “visual factory” describes how data and information are conveyed in a lean manufacturing environment. At its core, the goal is to indicate, at a glance, if something is performing well or if action needs to be taken to address a problem.

In a lean manufacturing environment, time spent gathering and collating the information is necessary, but it is also one of the 8 wastes. Therefore, spending less time gathering the data and more time acting on it is a critical part of running an effective factory floor. By using a combination of simple visual controls along with digital data, information can be communicated much more effectively and efficiently to those who need it, when they need it.

Examples of good visual controls include…

- Clearly labelled walkways within the factory

- Signs on equipment that is undergoing preventative maintenance

- Slip warning signs that indicate spillage areas

- Hourly tracker boards for tracking output (whiteboard or digital)

- An escalation process for production operators to flag issues (e.g. Andon lights or digital monitor)

- A team meeting board that shows live action items that are specific, measurable and timebound

How Does a Visual Factory Work?

The first step in implementing a visual factory strategy is to identify what needs to be communicated. This can be broken down into three categories…

Manufacturing process metrics:

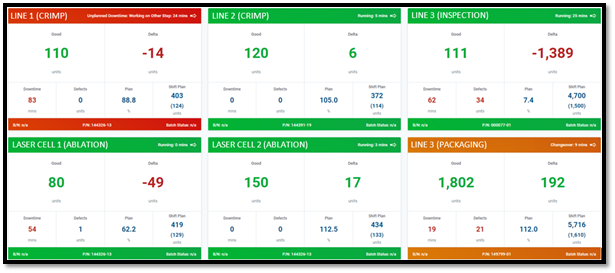

Production operators like to see how they are doing versus plan. It is also critical that the support teams can see how processes are performing so that they can respond to negative trends immediately. Typical process metrics include plan versus actual output, defects and downtime issues. This information is most effective when it is clearly visible and displayed in real-time. This is where digital information has clear advantages over the traditional whiteboard data that is difficult and time consuming to keep up-to-date.

Work instructions:

Work instructions are necessary to ensure that employees can complete tasks in the correct manner. They are typically posted in the production areas within easy reach of the production operators. Less words and more photos and graphics work best to ensure the instructions are interpreted correctly. This will also help minimise production errors. Bottom line, the more critical information that can be conveyed visually, the more it will improve communication and standardisation across the factory floor.

General plant information:

General plant information is typically posted in central locations throughout the factory where everybody has easy access to it. General information can alert employees to risks or dangers, can inform them of any upcoming events and also motivate them by communicating good news stories.

The second step in implementing a visual factory strategy is how to present and share the information. This is most effective when the information is displayed as close to the relevant work spaces as possible. These include:

Digital data:

Digital monitors that display real-time information about the status of a production process, cell or line and alerts support teams when production operators need assistance

Floor markings and signs:

Different coloured tapes and signs can quickly and effectively indicate areas where employees should walk but as importantly, where they shouldn’t walk. Entrance and exit signs can also create a quick visual cue as to how employees should move through a building

Signage and labels for materials:

Signs and labels that clearly identify raw materials, tools, key equipment and production aids can ensure that the right material or component is identified quickly but can also ensure that components are put back in the correct location after use. Companies often implement a 5S program in conjunction with their visual factory strategy to ensure that everything is assigned a “place” and that everything is kept in that place to ensure everybody has access to it as needed

Benefits

The ‘visual factory’ concept provides numerous benefits throughout the factory floor and beyond including:

- Increased productivity

- Quicker responses to downtime issues

- Fewer quality defects

- Fewer errors

- Less work in process (WIP) across the floor

- Safer workplace

- Increased employee motivation

- Better communication at all levels of the organisation

What does ‘good’ look like when monitoring manual processes?

At Kyzentree, we believe that the 1-10-20 rule is paramount to minimise disruptions and to maximise productivity…

- In 1 second, the visual controls should be able to tell if a process is running normally and is on track to meet the output plan. Using green to represent good status (e.g. output on track) and red to flag problems (e.g. workstation is in downtime) make this possible

- In 10 seconds, the visual controls should tell what the problem is if it’s not normal

- In 20 seconds, the visual controls should tell what action is to be taken, who is responsible for this and what support is needed

What is equally important is the effort required to gather and present the data. Less time gathering data and more time acting on it is critical to running an effective and efficient factory floor. Check out how our software, Kt-Pulse, can help you to monitor any manual or semi-automated process in real-time with 95% less effort than the traditional paper or whiteboard based systems.

Request a free demo: If you’d like to see for yourself how Kyzentree’s software, Kt-Pulse, can help you to visualise your manufacturing floor more effectively, book a one-to-one, no obligation consultation today and we’ll showcase the benefits to you.

About Kyzentree: We are a recognised leader in improving productivity by making it easy to visualise and manage manufacturing operations. We specialise in operator-driven processes. We have brought together a team of manufacturing, lean-sigma and technology experts to bring you our flagship product Kt-Pulse™. Kt-Pulse is an app-based software solution built exclusively for monitoring any type of manual assembly, inspection or packaging process.