We work with companies of all sizes and scale at a pace that suits you

Kt-Pulse™ is a leading edge solution for monitoring

and improving any operator-led manufacturing process

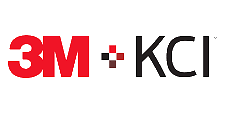

Kt-Pulse™ is a standalone solution that gives production operators a voice. The operators log good units, downtime events and quality losses as they occur using a simple touchscreen interface. Quick interactions with the app as they work, without leaving their workstation. Our dashboards and reports benefit all users including operators, team leads, engineers and managers

Traditional machine OEE software has its place in manufacturing, but Kt-Pulse is OEE for operator-driven manufacturing processes.

Kt-Pulse gives your processes a beat and characterises them with a new level of accuracy.

✅ Designed by manufacturing experts

✅ Track manual assembly, inspection or packaging processes

✅ Industry agnostic

✅ Cloud-based (no software installations)

✅ Up and running in less than 4 hours

✅ Easy to scale

✅ Free 30-day trial

✅ Free support

✅ Free upgrades

✅ Quick ROI

Increased productivity

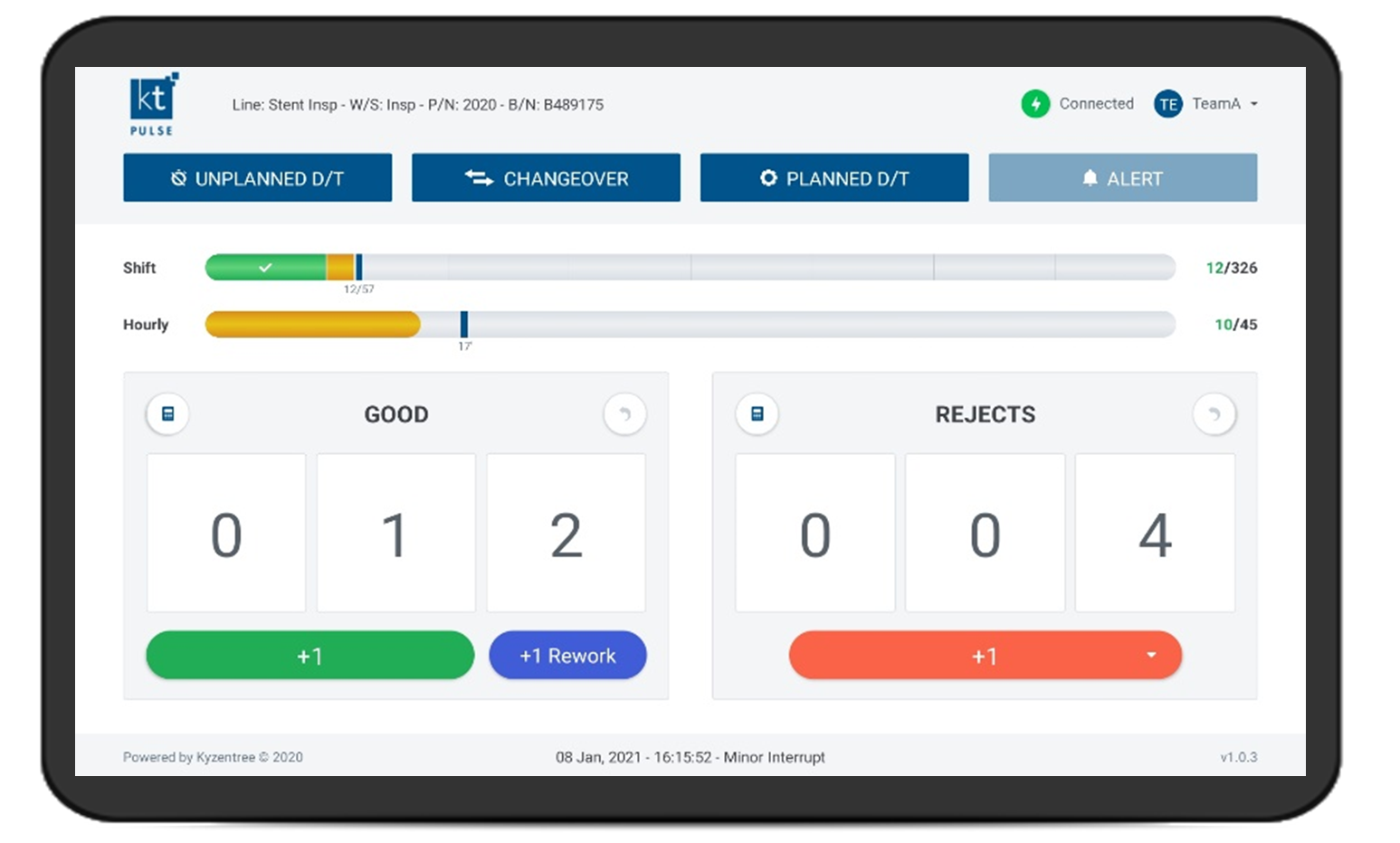

The Kt-Pulse collector app gives operators accurate, real-time visibility of the live plan versus output, keeping them on track to meet or exceed the shift plan

Production line on track....

Production line behind target .....

Quicker response to downtime and quality issues

With the Kt-Pulse live dashboards, issues are escalated more quickly to the right resources, reducing the impact of downtime and quality losses

Better team collaboration

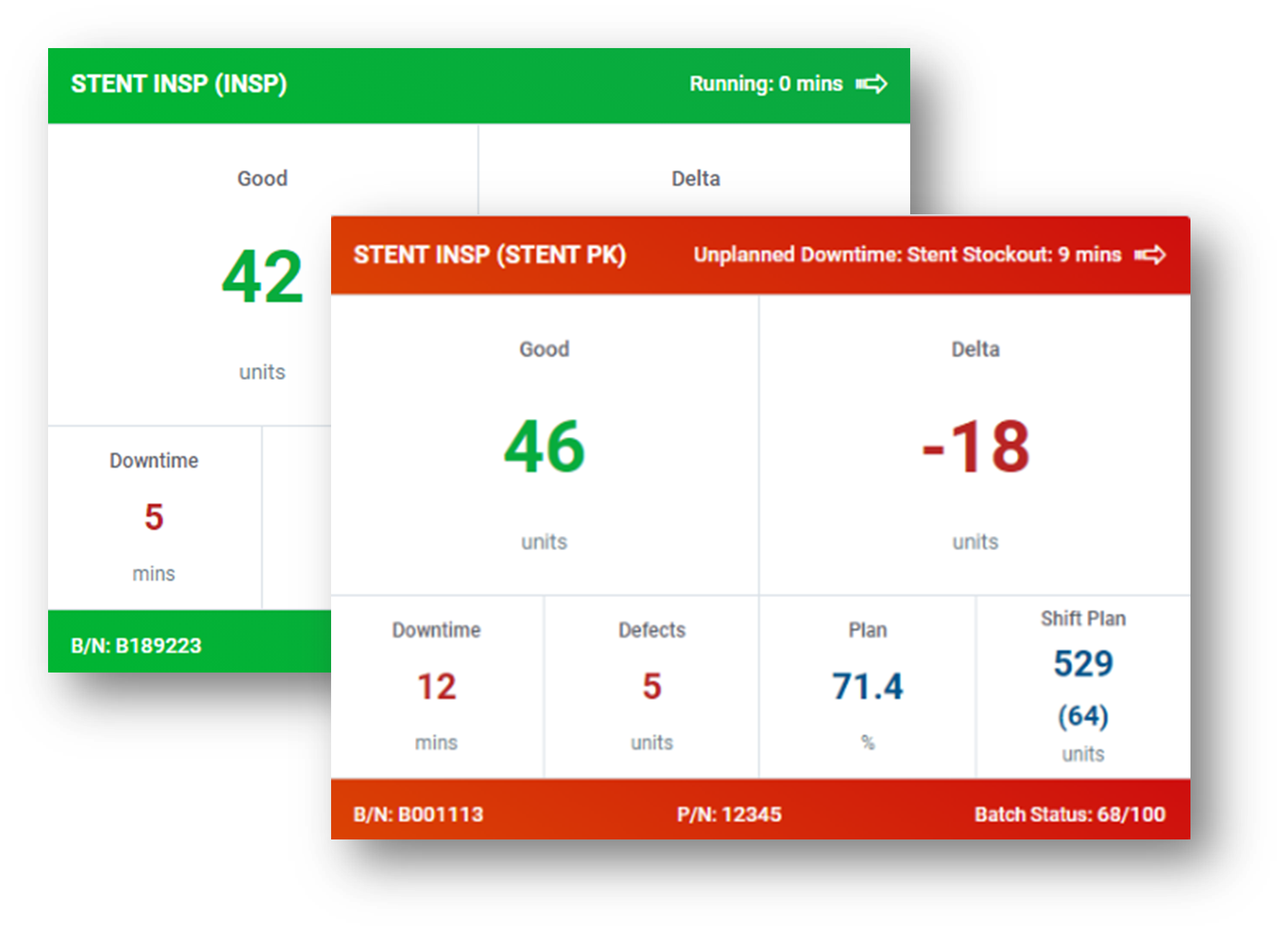

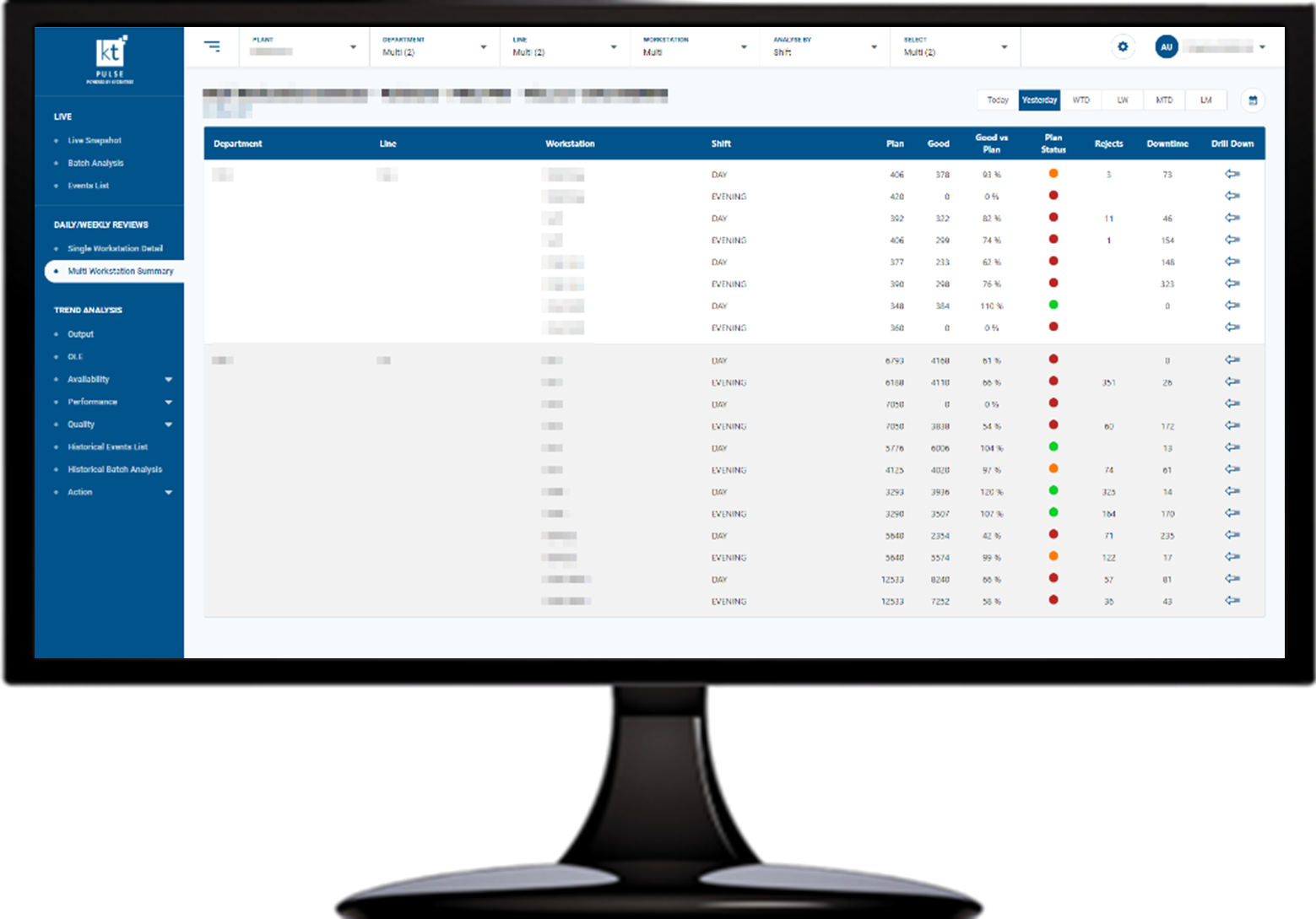

The shift summary dashboards keep the whole team aligned on how the manufacturing floor is operating and where to prioritise actions and support

More impactful improvement activity

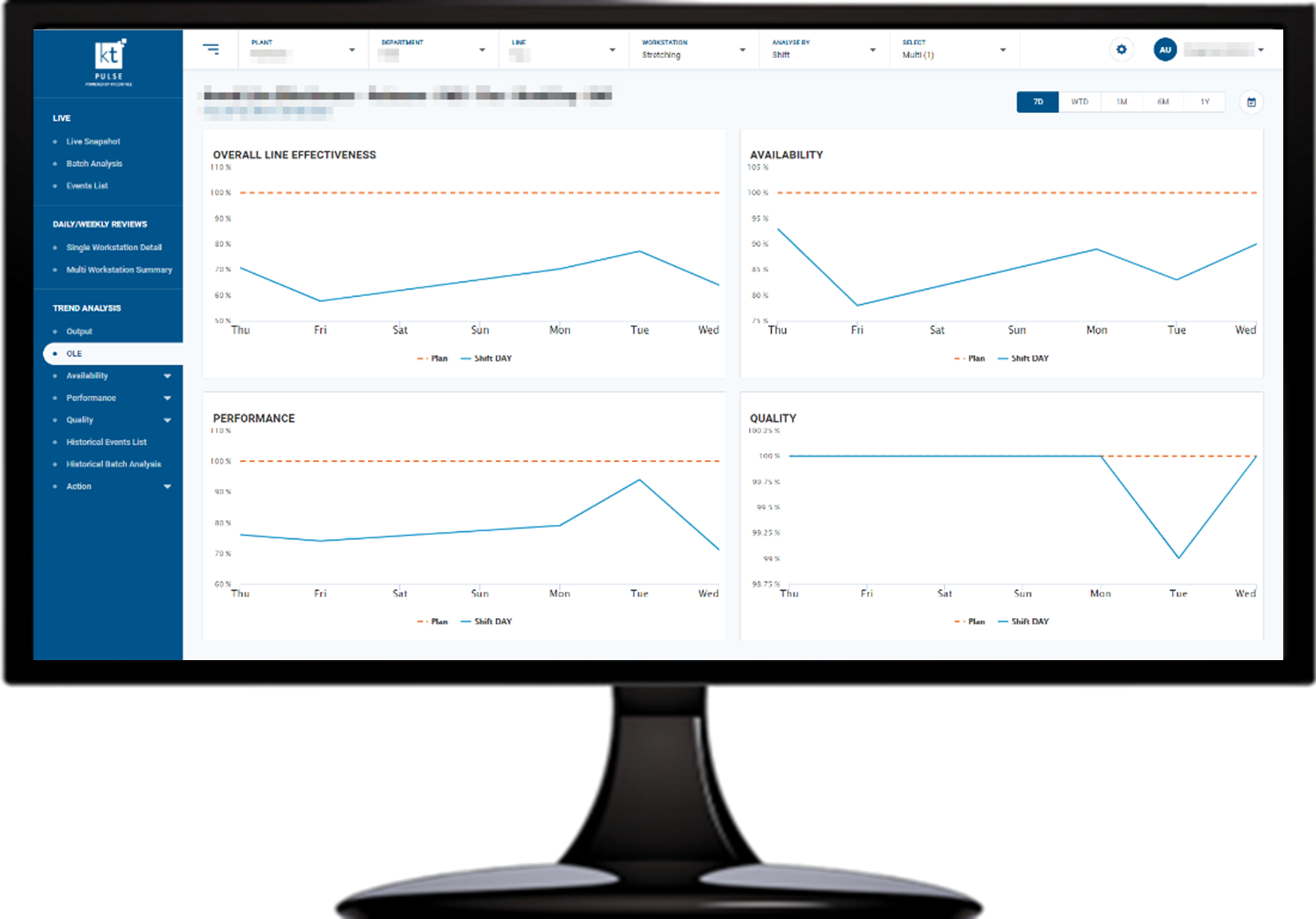

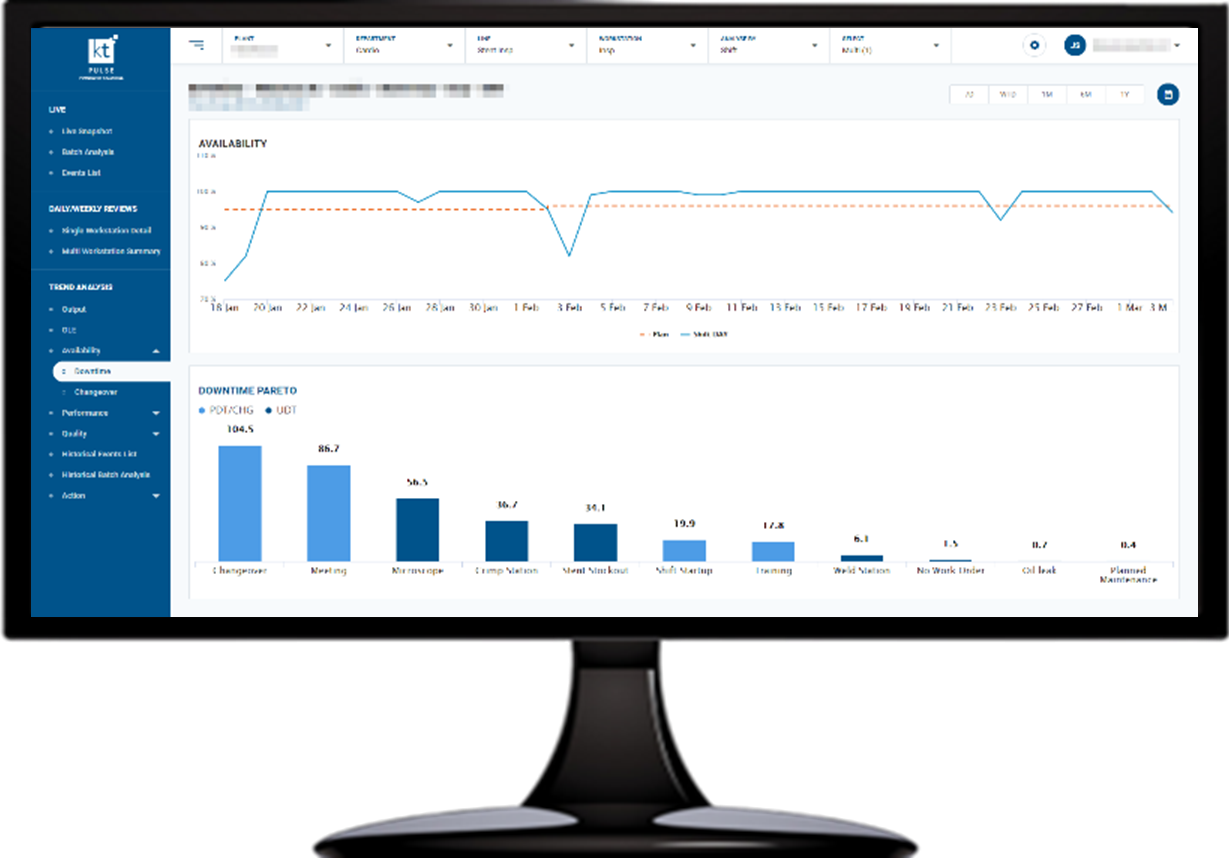

The trend analysis charts identify where the biggest downtime, quality and performance losses are occurring, giving you a powerful roadmap for improvement

Setup

Configure your production environment

Capture

Log production data in real-time

Visualise

Get new insights from the production floor

Improve

Collaborate and see the results

Production analytics made easy

Make data collection and reporting easy for any manual or semi-automated assembly, inspection or packaging process.

Is Kt-Pulse™ a good fit for your business?

Take our quick test

Have you manual or semi-automated processes?

Do you track production with checksheets and spreadsheets?

Do your resources spend lots of time maintaining cumbersome systems?

Do you lack accurate or actionable data?

Do you struggle to quantify downtime and quality losses?

Do you have difficulty seeing if production is on track?

“Kyzentree have a very proactive approach to improving their software, Kt-Pulse. They understand our challenges and offer support and advice. Excellent collaboration with customer to cater for the needs of the customer.”

Ger Hayes

Production Manager, Beckman Coulter

“Kyzentree have demonstrated they are a world class authority on manufacturing operations. They have delivered significant improvement to several of our medical device manufacturing lines, meeting or exceeding expectations.”

Brian O’Donnell

Project Manager, Creganna Medical

“EPC are using Kt-Pulse to track manufacturing performance and to measure improvements. The benefits include rapid identification and response to real-time production issues and accurate capture of production data.”

PJ Merrigan

Senior Project Manager, EuroPharma Concepts

“With KT-Pulse, we can carry out analysis that wasn’t possible before, certainly not to the required level of detail and confidence. Specifically, we can now determine the optimum resource level for each product code.”

Robert O’Connor

Senior Manufacturing Engineer, Aerogen

“Kyzentree helped us with a new production process which needed to ramp up volumes significantly. We were delighted with the outcome, which met our goals of increased productivity, improved yields and less stress on the team.”

Pauk Sherlock

Manufacturing Director, Merit Medical

Supported by